1. Essential Structure and Quantum Characteristics of Molybdenum Disulfide

1.1 Crystal Architecture and Layered Bonding Mechanism

(Molybdenum Disulfide Powder)

Molybdenum disulfide (MoS TWO) is a change steel dichalcogenide (TMD) that has become a foundation material in both classical industrial applications and advanced nanotechnology.

At the atomic level, MoS â takes shape in a split framework where each layer consists of a plane of molybdenum atoms covalently sandwiched between two airplanes of sulfur atoms, developing an S– Mo– S trilayer.

These trilayers are held together by weak van der Waals pressures, permitting very easy shear in between nearby layers– a building that underpins its exceptional lubricity.

One of the most thermodynamically steady phase is the 2H (hexagonal) phase, which is semiconducting and shows a straight bandgap in monolayer form, transitioning to an indirect bandgap in bulk.

This quantum arrest effect, where digital residential or commercial properties change drastically with thickness, makes MoS â a model system for studying two-dimensional (2D) materials past graphene.

In contrast, the much less common 1T (tetragonal) stage is metal and metastable, frequently induced via chemical or electrochemical intercalation, and is of interest for catalytic and energy storage applications.

1.2 Electronic Band Structure and Optical Response

The electronic properties of MoS â are very dimensionality-dependent, making it a distinct system for exploring quantum sensations in low-dimensional systems.

Wholesale kind, MoS two behaves as an indirect bandgap semiconductor with a bandgap of roughly 1.2 eV.

Nevertheless, when thinned down to a solitary atomic layer, quantum confinement effects create a change to a straight bandgap of about 1.8 eV, located at the K-point of the Brillouin area.

This change allows strong photoluminescence and reliable light-matter interaction, making monolayer MoS two highly appropriate for optoelectronic devices such as photodetectors, light-emitting diodes (LEDs), and solar batteries.

The transmission and valence bands exhibit substantial spin-orbit combining, leading to valley-dependent physics where the K and K â² valleys in energy area can be uniquely resolved making use of circularly polarized light– a phenomenon referred to as the valley Hall effect.

( Molybdenum Disulfide Powder)

This valleytronic capability opens up brand-new methods for information encoding and handling past standard charge-based electronics.

Additionally, MoS â demonstrates strong excitonic results at space temperature because of decreased dielectric testing in 2D form, with exciton binding powers getting to numerous hundred meV, far exceeding those in standard semiconductors.

2. Synthesis Techniques and Scalable Manufacturing Techniques

2.1 Top-Down Exfoliation and Nanoflake Fabrication

The isolation of monolayer and few-layer MoS two started with mechanical exfoliation, a strategy comparable to the “Scotch tape approach” made use of for graphene.

This approach yields top notch flakes with marginal flaws and excellent digital buildings, ideal for basic study and model device fabrication.

However, mechanical peeling is inherently restricted in scalability and side size control, making it improper for commercial applications.

To resolve this, liquid-phase exfoliation has been developed, where bulk MoS â is spread in solvents or surfactant remedies and based on ultrasonication or shear blending.

This technique generates colloidal suspensions of nanoflakes that can be deposited through spin-coating, inkjet printing, or spray covering, allowing large-area applications such as flexible electronics and coatings.

The size, density, and flaw thickness of the scrubed flakes rely on handling criteria, consisting of sonication time, solvent choice, and centrifugation speed.

2.2 Bottom-Up Development and Thin-Film Deposition

For applications needing uniform, large-area movies, chemical vapor deposition (CVD) has actually become the dominant synthesis route for premium MoS two layers.

In CVD, molybdenum and sulfur precursors– such as molybdenum trioxide (MoO â) and sulfur powder– are evaporated and reacted on heated substrates like silicon dioxide or sapphire under regulated environments.

By tuning temperature level, stress, gas circulation rates, and substratum surface area power, scientists can grow continuous monolayers or piled multilayers with manageable domain size and crystallinity.

Different techniques include atomic layer deposition (ALD), which uses remarkable thickness control at the angstrom level, and physical vapor deposition (PVD), such as sputtering, which is compatible with existing semiconductor manufacturing facilities.

These scalable methods are critical for incorporating MoS two right into commercial electronic and optoelectronic systems, where uniformity and reproducibility are vital.

3. Tribological Performance and Industrial Lubrication Applications

3.1 Devices of Solid-State Lubrication

One of the earliest and most prevalent uses MoS two is as a solid lube in environments where fluid oils and greases are ineffective or unwanted.

The weak interlayer van der Waals forces permit the S– Mo– S sheets to slide over one another with very little resistance, resulting in an extremely reduced coefficient of friction– typically in between 0.05 and 0.1 in dry or vacuum cleaner problems.

This lubricity is particularly valuable in aerospace, vacuum cleaner systems, and high-temperature equipment, where standard lubes might vaporize, oxidize, or break down.

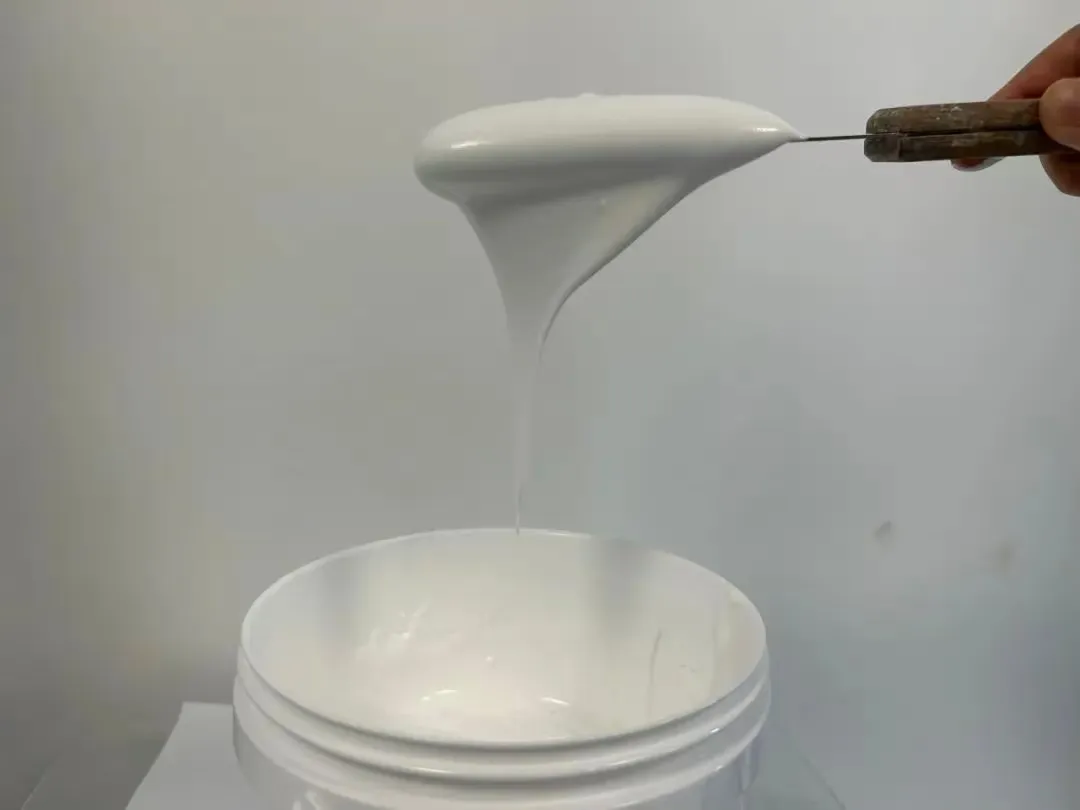

MoS two can be used as a completely dry powder, bonded finishing, or distributed in oils, greases, and polymer composites to enhance wear resistance and decrease rubbing in bearings, equipments, and sliding get in touches with.

Its efficiency is additionally improved in humid settings because of the adsorption of water molecules that serve as molecular lubes in between layers, although excessive dampness can lead to oxidation and degradation in time.

3.2 Compound Integration and Put On Resistance Enhancement

MoS â is frequently incorporated right into steel, ceramic, and polymer matrices to create self-lubricating compounds with extended life span.

In metal-matrix compounds, such as MoS â-reinforced light weight aluminum or steel, the lube phase decreases friction at grain limits and protects against glue wear.

In polymer composites, particularly in engineering plastics like PEEK or nylon, MoS two improves load-bearing ability and reduces the coefficient of friction without significantly compromising mechanical strength.

These composites are utilized in bushings, seals, and sliding parts in vehicle, industrial, and aquatic applications.

Additionally, plasma-sprayed or sputter-deposited MoS two layers are utilized in armed forces and aerospace systems, consisting of jet engines and satellite devices, where integrity under extreme conditions is critical.

4. Arising Roles in Energy, Electronics, and Catalysis

4.1 Applications in Power Storage and Conversion

Past lubrication and electronics, MoS two has acquired importance in power technologies, particularly as a stimulant for the hydrogen advancement reaction (HER) in water electrolysis.

The catalytically active websites are located primarily at the edges of the S– Mo– S layers, where under-coordinated molybdenum and sulfur atoms promote proton adsorption and H â formation.

While mass MoS two is much less active than platinum, nanostructuring– such as developing vertically straightened nanosheets or defect-engineered monolayers– drastically enhances the density of active side sites, coming close to the performance of noble metal catalysts.

This makes MoS TWO an appealing low-cost, earth-abundant choice for green hydrogen production.

In energy storage space, MoS â is checked out as an anode product in lithium-ion and sodium-ion batteries as a result of its high theoretical capacity (~ 670 mAh/g for Li âº) and split structure that permits ion intercalation.

Nonetheless, difficulties such as volume development throughout cycling and limited electric conductivity require techniques like carbon hybridization or heterostructure formation to improve cyclability and price efficiency.

4.2 Assimilation right into Versatile and Quantum Devices

The mechanical flexibility, transparency, and semiconducting nature of MoS two make it an excellent prospect for next-generation adaptable and wearable electronics.

Transistors produced from monolayer MoS two show high on/off ratios (> 10 EIGHT) and movement worths approximately 500 centimeters TWO/ V · s in suspended forms, enabling ultra-thin reasoning circuits, sensing units, and memory gadgets.

When integrated with other 2D materials like graphene (for electrodes) and hexagonal boron nitride (for insulation), MoS â types van der Waals heterostructures that resemble standard semiconductor devices but with atomic-scale precision.

These heterostructures are being checked out for tunneling transistors, photovoltaic cells, and quantum emitters.

Additionally, the strong spin-orbit coupling and valley polarization in MoS two provide a foundation for spintronic and valleytronic devices, where details is encoded not in charge, but in quantum degrees of freedom, possibly leading to ultra-low-power computing paradigms.

In summary, molybdenum disulfide exhibits the merging of timeless product utility and quantum-scale advancement.

From its function as a durable solid lubricant in extreme environments to its feature as a semiconductor in atomically slim electronics and a catalyst in lasting power systems, MoS two remains to redefine the limits of materials scientific research.

As synthesis strategies enhance and assimilation approaches develop, MoS two is positioned to play a central function in the future of innovative manufacturing, tidy energy, and quantum information technologies.

Distributor

RBOSCHCO is a trusted global chemical material supplier & manufacturer with over 12 years experience in providing super high-quality chemicals and Nanomaterials. The company export to many countries, such as USA, Canada, Europe, UAE, South Africa, Tanzania, Kenya, Egypt, Nigeria, Cameroon, Uganda, Turkey, Mexico, Azerbaijan, Belgium, Cyprus, Czech Republic, Brazil, Chile, Argentina, Dubai, Japan, Korea, Vietnam, Thailand, Malaysia, Indonesia, Australia,Germany, France, Italy, Portugal etc. As a leading nanotechnology development manufacturer, RBOSCHCO dominates the market. Our professional work team provides perfect solutions to help improve the efficiency of various industries, create value, and easily cope with various challenges. If you are looking for moly powder lubricant, please send an email to: sales1@rboschco.com

Tags: molybdenum disulfide,mos2 powder,molybdenum disulfide lubricant

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us