Intro to 3D Printing and Round Tungsten Powder

As additive production continues to reshape the landscape of commercial production, the need for high-performance products has actually never ever been higher. Among the most appealing materials getting in the 3D printing field is spherical tungsten powder– a material known for its outstanding density, thermal resistance, and mechanical strength. This post discovers the residential or commercial properties, applications, and future potential of round tungsten powder in 3D printing, highlighting how it is pushing the borders of what’s possible in advanced manufacturing.

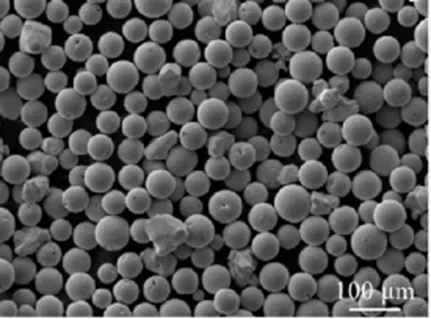

(Spherical Tungsten Powder)

Special Residences of Spherical Tungsten Powder

Spherical tungsten powder is differentiated by its near-perfect bit morphology, high purity, and excellent flowability– attributes important for effective 3D printing processes such as selective laser melting (SLM) and electron beam of light melting (EBM). Tungsten itself is just one of the hardest metals recognized, with a melting factor surpassing 3,400 ° C and amazing resistance to use, rust, and contortion under extreme conditions. When refined right into fine, spherical bits, it becomes ideal for generating thick, high-precision components made use of in aerospace, defense, and nuclear markets. These distinct characteristics placement round tungsten powder as an essential enabler of next-generation additive manufacturing technologies.

Applications Across High-Tech Industries

Aerospace and Protection: In aerospace and defense fields, where performance under extreme problems is non-negotiable, round tungsten powder is increasingly utilized to make heat shields, radiation protecting elements, and high-strength structural parts. Its ability to withstand heats and withstand oxidation makes it appropriate for jet engine parts, rocket assistance systems, and satellite real estates. Additive manufacturing enables complex geometries that were previously impossible or cost-prohibitive utilizing conventional machining methods.

Atomic Energy and Radiation Security: Because of its high density and atomic number, tungsten is an exceptional product for radiation shielding. Elements made from 3D published spherical tungsten powder are being developed for use in atomic power plants, medical imaging tools, and particle accelerators. The precision made it possible for by 3D printing ensures optimal geometry for radiation absorption while lessening product waste.

Industrial Tools and Wear-Resistant Components: The firmness and use resistance of tungsten make it suitable for reducing tools, passes away, and other commercial components exposed to rough settings. By utilizing 3D printing, producers can produce customized tooling with interior cooling channels or latticework frameworks that improve performance and expand life span. This degree of personalization was formerly unattainable through standard production methods.

Electronic Devices and Semiconductor Production: As digital gadgets become more portable and effective, thermal monitoring comes to be critical. Spherical tungsten powder makes it possible for the fabrication of heat sinks and substrates with tailored thermal expansion coefficients, aligning them with semiconductor materials like silicon and gallium nitride. This compatibility boosts dependability and longevity in high-performance electronic devices.

Market Patterns and Development Drivers

Innovations in Steel Ingredient Manufacturing: The quick advancement of metal 3D printing innovations– specifically powder bed combination– is driving raised rate of interest in unique materials like tungsten. As printers come to be a lot more capable and budget-friendly, the adoption of round tungsten powder is expected to rise across multiple sectors. Improved software control and boosted recoating systems likewise add to bulk quality and consistency.

Expanding Need for High-Performance Products: With sectors striving for higher performance, longer lifespans, and minimized maintenance, there is an expanding shift towards materials that can do reliably in severe atmospheres. Round tungsten powder meets this demand by providing premium mechanical and thermal residential or commercial properties contrasted to traditional alloys.

Modification and Lightweighting Fads: Among the core advantages of 3D printing is the capability to generate light-weight yet solid parts. Round tungsten powder sustains these trends by enabling topology-optimized layouts that lower mass without endangering stamina. This is especially useful in aerospace and automotive design, where weight cost savings translate straight into gas effectiveness and performance gains.

(Spherical Tungsten Powder)

Obstacles and Technical Considerations

In spite of its numerous advantages, collaborating with spherical tungsten powder in 3D printing provides several obstacles. Its high reflectivity and thermal conductivity need accurate control over laser or electron light beam criteria to accomplish correct melting and bonding. In addition, post-processing steps such as warm isostatic pressing (HIP) may be essential to eliminate porosity and make certain complete thickness. Powder handling and recycling additionally position technological hurdles because of the product’s high details gravity and abrasiveness. Resolving these concerns will call for ongoing technology in printer style, process optimization, and powder solution.

Future Potential Customers and Emerging Opportunities

Looking in advance, the combination of spherical tungsten powder right into 3D printing operations is positioned for substantial development. Research is ongoing right into hybrid products, such as tungsten matrix composites strengthened with carbon nanotubes or ceramic stages, which could even more improve mechanical properties. Additionally, improvements in binder jetting and straight power deposition technologies may open up new paths for large-scale tungsten element construction. As sustainability becomes a central emphasis, initiatives are also underway to boost powder reusability and lower the environmental footprint of tungsten mining and handling.

Verdict: Forming the Future of Precision Manufacturing

To conclude, round tungsten powder stands for a significant leap ahead in the abilities of 3D printing modern technology. Its mix of severe thermal resistance, mechanical toughness, and printability positions it as a critical product for high-performance applications throughout aerospace, defense, nuclear, and electronic devices industries. While technological obstacles remain, recurring advancements in both products science and printing modern technologies assure to open also greater potential. As additive manufacturing continues to evolve, round tungsten powder will play a pivotal duty in shaping the future of precision, durability, and efficiency in commercial manufacturing.

Distributor

TRUNNANO is a supplier of Spherical Tungsten Powder with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about Spherical Tungsten Powder, please feel free to contact us and send an inquiry(sales5@nanotrun.com).

Tag: tungsten,tung sten,tungsten powder

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us