Betaine surfactants sodium laureth sulfate

Betaine surfactants

It is produced by the response of fatty tertiary amines and sodium chloroacetate, consisting of cocoylpropyl betaine, dodecyl betaine, cetyl betaine, and lauroyl propyl betaine. It is milder than the very first 3 and is presently the primary surfactant in infant hair shampoo.

In 1940, the American DuPont Firm designed and applied this sort of substance. Like amino acid surfactants, this sort of surfactant has solid detergency and low inflammation, and the service is weakly acidic. Pet experiments have actually shown that this type of substance is much less harmful. It is an ideal surfactant.

( surfactants in shampoos)

Amino acid surfactants

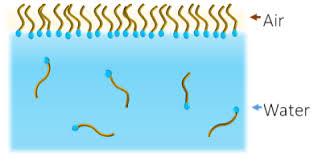

Made from a combination of coconut oil and amino acids, it is risk-free, gentle, and non-irritating. The most essential thing is that it is normally weakly acidic and satisfies the pH requirements of healthy and balanced skin and hair. It is the suitable surfactant in baby hair shampoo. They are “cocoyl glycine,” “cocoyl glutamate disodium,” and so on

From the point of view of chemical residential properties, its pH worth is between 5.5 and 6.5, which is weakly acidic and near to the pH worth of human skin. Thus, it is mild and skin-friendly and ideal for all hair types; amino acid surfactants are zwitterionic and easily soluble in water. It is simple to rinse tidy.

Yet it likewise has restrictions. Amino acid surfactants are numerous to loads of times extra pricey than average surfactants, and a lot of are shampoos specifically created babies and young kids. The disadvantages of amino acid surfactants are that they are not abundant in foam and have weak decontamination ability.

The phenomenon of solidification and turbidity of surfactants in winter is mainly because of the reduced temperature level causing a few of its parts to crystallize or speed up.

(surfactants in shampoos)

Suppose surfactant solidifies and comes to be turbid in winter months?

This is a physical sensation and does not have a considerable influence on the effectiveness of surfactants. In order to fix this problem, the complying with techniques can be taken:

1. Increase the temperature: Position the surfactant in a warm atmosphere or enhance its temperature by heating to ensure that the taken shape or precipitated components will slowly dissolve and the surfactant will go back to a clear state. Nevertheless, it should be noted that the temperature needs to be prevented when heating to prevent affecting the surfactant’s efficiency.

2. Stirring: For surfactants that have solidified or ended up being turbid, they can be restored to a consistent state by mixing. Stirring can assist taken shape or precipitated components redisperse into the fluid and boost surfactant clarity.

3. Add solvent: In many cases, a suitable amount of solvent can be contributed to weaken the surfactant, consequently boosting its coagulation and turbidity. Nevertheless, the added solvent need to be compatible with the surfactant and should not influence its use effect.

Supplier of Surfactant

TRUNNANO is a supplier of surfactant with over 12 years experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for high-quality sodium laureth sulfate, please feel free to contact us and send an inquiry.

Inquiry us